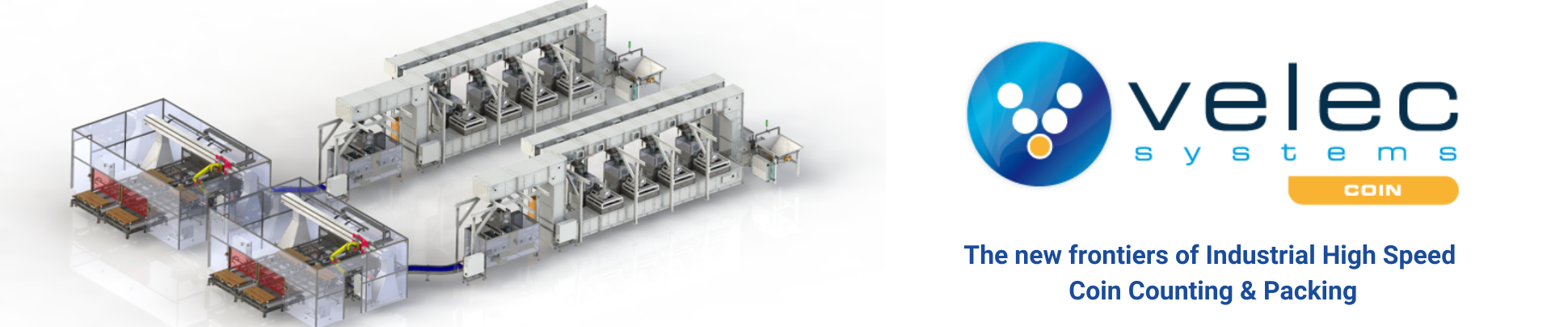

We are the specialist of engineering and manufacturing completes lines for the coin industry. We develop complete turnkey solutions from sorting and handling naked products before and after processing to primary and secondary packing including all types of palletizing solutions.

Velec Systems designs coin packaging lines that will maximize your production, and this through high-performance machines and fully automated packaging system, while noz creating traceability outside your mint.

“Our industrial lines must be as simple and intuitive to use as a smartphone. Our leitmotiv: keep it simple and smart.” LOÏC POLLET – CEO

Have a look at our work here

Velec Youtube Channel

VELEC Systems coin counters count, verify and bag coins or blanks. More…

With the experience VELEC systems has been able to develop clear and precise supervision solutions that satisfy the production chain :

- Operators with simple menus and setup assistance

- Maintenance with integrated maintenance task management, control of each element of lines

- Production managers: with precise management of production flows and real-time adaptability, a visual display of element rates and the ability to interact with the line directly from their computers on a web browser.

- Supervisors: With detailed production reports, performance graphs, and more.

Our supervision solutions are equipped with a powerful traceability manager that allows you to know at any time the status of an element inside your mint..as well as outside

Whatever your needs, our technical experts are at your disposal to study all your needs (dimensions and shapes of coins, required output, batch sizes, packaging configurations) and design an automatic packaging line perfectly adapted to your facilities. All solutions are possible from the single industrial high-speed counting machine to the fully automated line integrating a complete intuitive touch screen supervision interfacing with your ERP.

This line consists in preparing the blanks for the coin minting process, and this, through several steps handled by high-performance machines. Thanks to hoppers, the blanks will be brang in a controlled manner where they will be weighed and identified. Our fully automatized line simplify you the bucket transfer by a tightening mechanism. As a result, a main feeding conveyor will feed 2 parallel distribution bucket conveyors, where empty buckets will be tilted and transfer batch of a particular denomination. To secure a perfect tightness, the same tightening mechanism will be placed on each main feeding bucket conveyor.

We are the specialist of engineering and manufacturing completes lines for the coin industry. We develop complete turnkey solutions from sorting and handling naked products before and after processing to primary and secondary packing including all types of palletizing solutions.

Velec Systems designs coin packaging lines that will maximize your production, and this through high-performance machines and fully automated packaging system, while noz creating traceability outside your mint.

“Our industrial lines must be as simple and intuitive to use as a smartphone. Our leitmotiv: keep it simple and smart.” LOÏC POLLET – CEO

Have a look at our work here

Velec Youtube Channel

VELEC Systems coin counters count, verify and bag coins or blanks. More…

With the experience VELEC systems has been able to develop clear and precise supervision solutions that satisfy the production chain :

- Operators with simple menus and setup assistance

- Maintenance with integrated maintenance task management, control of each element of lines

- Production managers: with precise management of production flows and real-time adaptability, a visual display of element rates and the ability to interact with the line directly from their computers on a web browser.

- Supervisors: With detailed production reports, performance graphs, and more.

Our supervision solutions are equipped with a powerful traceability manager that allows you to know at any time the status of an element inside your mint..as well as outside

Whatever your needs, our technical experts are at your disposal to study all your needs (dimensions and shapes of coins, required output, batch sizes, packaging configurations) and design an automatic packaging line perfectly adapted to your facilities. All solutions are possible from the single industrial high-speed counting machine to the fully automated line integrating a complete intuitive touch screen supervision interfacing with your ERP.

This line consists in preparing the blanks for the coin minting process, and this, through several steps handled by high-performance machines. Thanks to hoppers, the blanks will be brang in a controlled manner where they will be weighed and identified. Our fully automatized line simplify you the bucket transfer by a tightening mechanism. As a result, a main feeding conveyor will feed 2 parallel distribution bucket conveyors, where empty buckets will be tilted and transfer batch of a particular denomination. To secure a perfect tightness, the same tightening mechanism will be placed on each main feeding bucket conveyor.

Velec Systems

info@velecsystems.com

Tel +33 (0)3 20 75 44 98