Innovative equipment technology and finishing processes are the reason, why Rösler is the leading supplier for the coin industry. Mints and coin blank manufacturers all over the world rely on the innovative Rösler technologies for optimum surface finishes.

Pre-treatment of circulation coin blanks (after stamping)

In a direct link with the stamping press the coin blanks are transferred to the mechanical/chemical cleaning station. Oil residues are removed and the edges are broken. During the subsequent drying process the coin blanks are prepared for the heat treatment operation. The process water is cleaned for re-use in the process. This saves valuable resources.

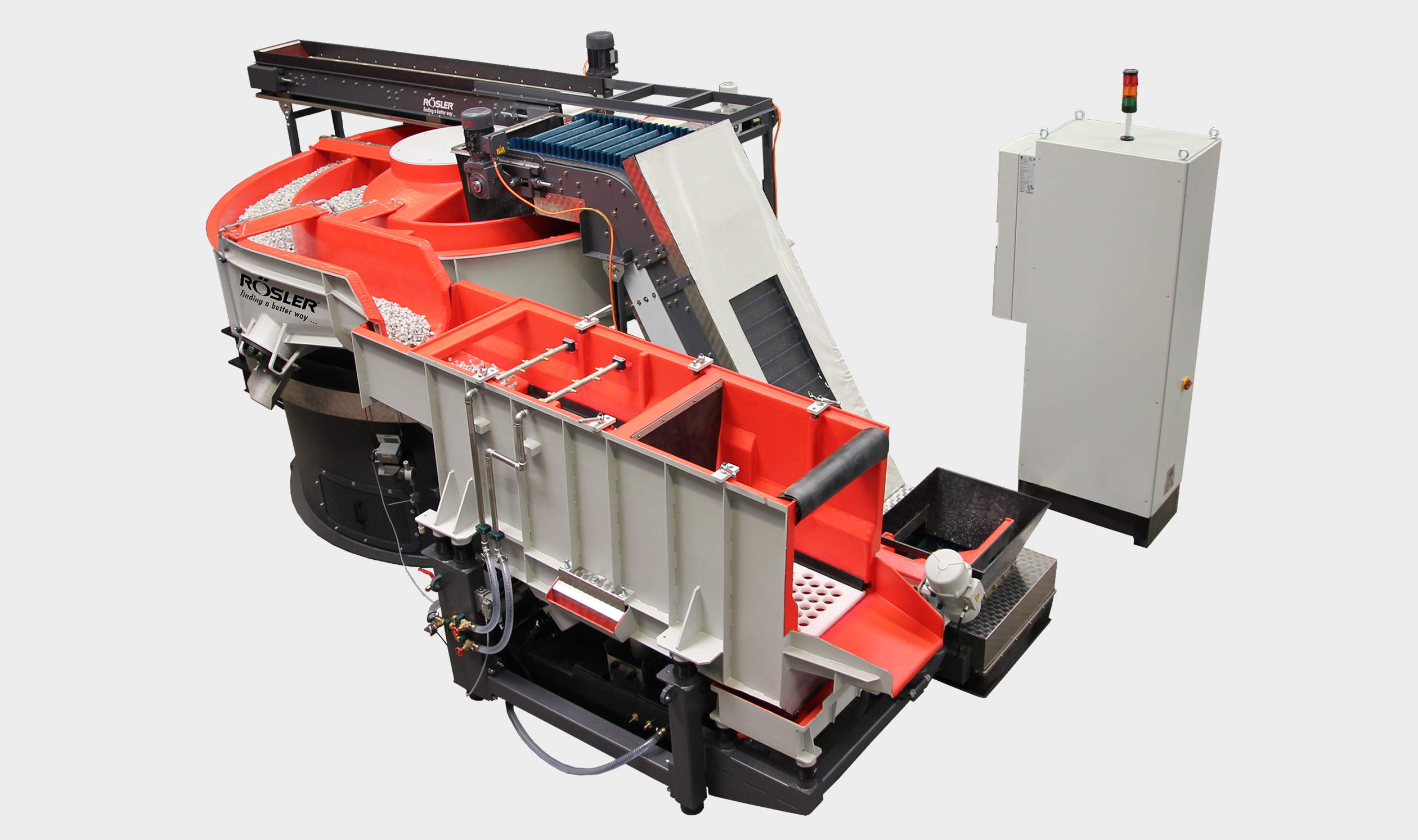

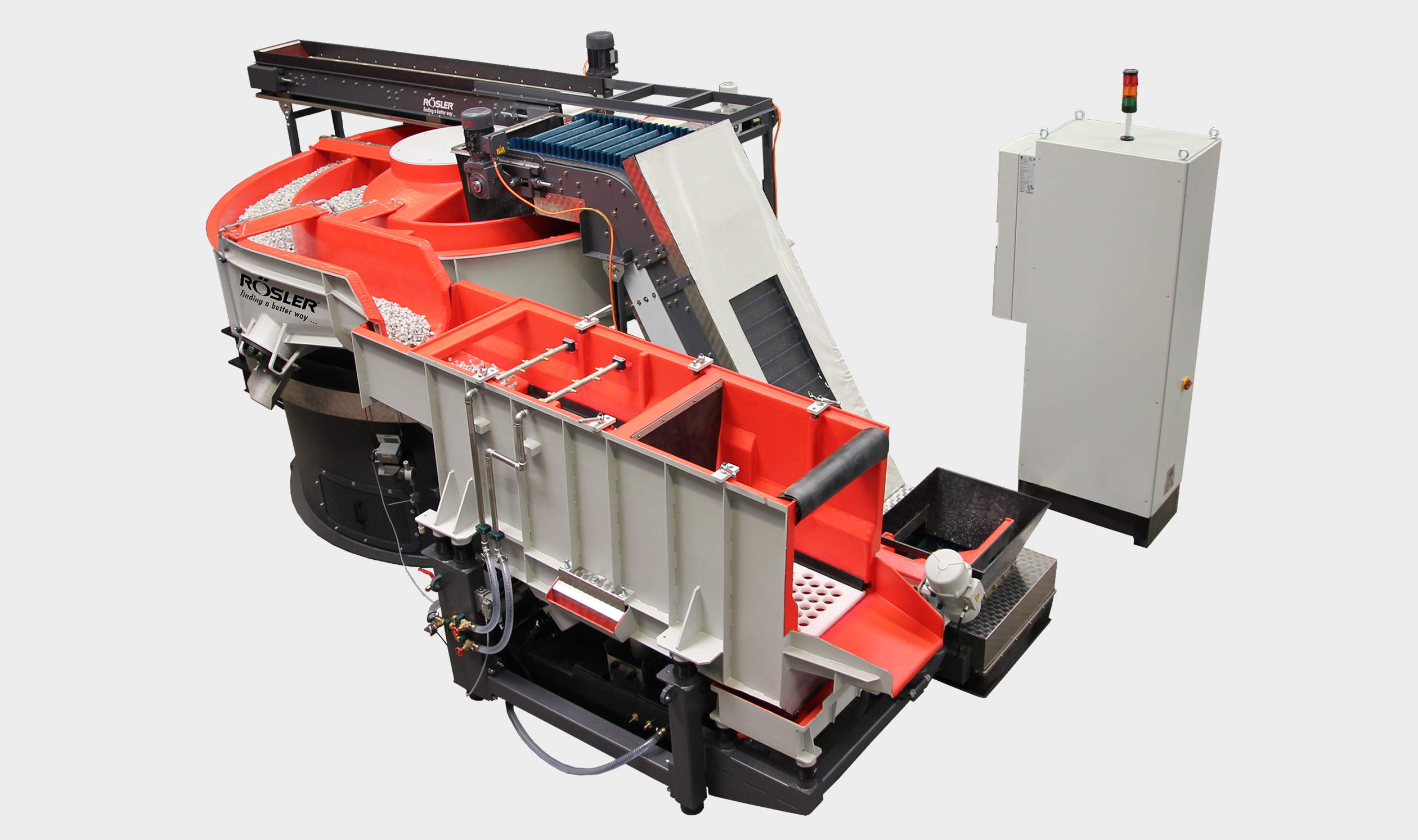

Cleaning / Washing / Polishing of circulation coin blanks

After plating or heat treatment we are cleaning the blanks by removing any surface contaminants. The resulting surface finish is ideal for the subsequent minting operation. Fully automatic processing, state-of-the-art equipment technology and batch capacities of up to 450 kg guarantee repeatable, high-quality coin blank finishes. Rösler driers will dry the blanks free of scratches and dust and with energy savings of up to 70%. During the drying process the coin blanks will not get warmer than 35°C. We have applied for a patent (DE 10 2019 131 105.5) for this energy-efficient drying technology.

High-value collector coins

High-value blanks made from precious metals are gently processed in special finishing equipment, model range E-SA, without any nicks or scratches. To prevent any damage, contrary to other equipment suppliers, we refrain from any tumbling steps. Modern control systems guarantee absolute process stability and repeatable finishing results.

Coining tools

Surface treatment before countersinking, but also the grinding and polishing of engraved coining dies is possible with mass finishing. With its high gloss polishing technology Rösler also offers a cost-effective alternative to hand polishing.

Process water cleaning

The process water used in finishing operations can be mechanically cleaned for recycling, treated in evaporators or cleaned in traditional chemical treatment plants for re-use.

Processing media and compounds

R&D and process engineering are constantly developing new products for optimal and economic surface treatment. Processing media and compounds, made in house, are high-quality tools for excellent surface finishes.

We can offer a solution for every application!

Our coin blank finishing experts will be happy to answer your questions!

Rüdiger Böhm

Manager Global R&D

Mass Finishing

Tel.: +49 9533 924 280

E-Mail: R.Boehm@rosler.com

David Soldan

Export Sales Manager

Mass Finishing Machinery

Tel.: +49 9533 924 814

E-Mail: D.Soldan@rosler.com

Pre-treatment of circulation coin blanks (after stamping)

In a direct link with the stamping press the coin blanks are transferred to the mechanical/chemical cleaning station. Oil residues are removed and the edges are broken. During the subsequent drying process the coin blanks are prepared for the heat treatment operation. The process water is cleaned for re-use in the process. This saves valuable resources.

Cleaning / Washing / Polishing of circulation coin blanks

After plating or heat treatment we are cleaning the blanks by removing any surface contaminants. The resulting surface finish is ideal for the subsequent minting operation. Fully automatic processing, state-of-the-art equipment technology and batch capacities of up to 450 kg guarantee repeatable, high-quality coin blank finishes. Rösler driers will dry the blanks free of scratches and dust and with energy savings of up to 70%. During the drying process the coin blanks will not get warmer than 35°C. We have applied for a patent (DE 10 2019 131 105.5) for this energy-efficient drying technology.

High-value collector coins

High-value blanks made from precious metals are gently processed in special finishing equipment, model range E-SA, without any nicks or scratches. To prevent any damage, contrary to other equipment suppliers, we refrain from any tumbling steps. Modern control systems guarantee absolute process stability and repeatable finishing results.

Coining tools

Surface treatment before countersinking, but also the grinding and polishing of engraved coining dies is possible with mass finishing. With its high gloss polishing technology Rösler also offers a cost-effective alternative to hand polishing.

Process water cleaning

The process water used in finishing operations can be mechanically cleaned for recycling, treated in evaporators or cleaned in traditional chemical treatment plants for re-use.

Processing media and compounds

R&D and process engineering are constantly developing new products for optimal and economic surface treatment. Processing media and compounds, made in house, are high-quality tools for excellent surface finishes.

We can offer a solution for every application!

Our coin blank finishing experts will be happy to answer your questions!

Rüdiger Böhm

Manager Global R&D

Mass Finishing

Tel.: +49 9533 924 280

E-Mail: R.Boehm@rosler.com

David Soldan

Export Sales Manager

Mass Finishing Machinery

Tel.: +49 9533 924 814

E-Mail: D.Soldan@rosler.com

Rösler Oberflächentechnik GmbH

Vorstadt 1

DE – 91690 Untermerzbach